Offset Print

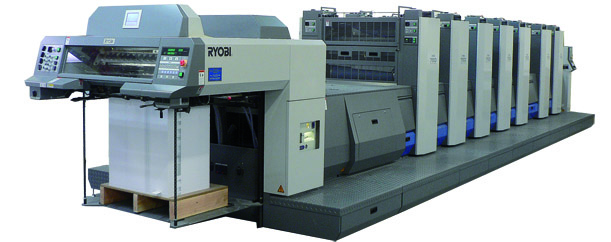

To cope with market demand for shorter delivery times and quality for printed materials Otago Daily Times Print has installed a 6 colour press with aqueous coating and IR drying.

Fifth and sixth colour printing enhance the visual effect of printed materials, such as custom colours and supplemental colours, including gold, silver, fluorescent and opalescent inks. The press can easily handle spot-colour printing for logos or company names which use specialty inks.

The Ryobi 756P is a press that can handle a wide range of paper from very thin invoice slips to flyers, brochures, tickets, books, catalogues, posters, as well as thicker paper used for cover and package printing. the press is also able to feed paper sizes up to 750 x 600mm (maximum image size 744 x 545mm) for greater versatility.

Aqueous coating is a water based coating applied after print, while the paper is still on the press, giving a gloss, silk or matt finish to the artwork. Aqueous coating also helps stop the underlaying ink from smudging or rubbing off.

Product finishing in sheet-fed offset printing in combination with increased productivity is hardly possible without the support of dryer systems. By heating the ink (or coating) it reduces viscosity and greatly improves the penetration into the stock, therefore the printed sheet is dry as it comes off the press.